By Mark Nugent

With freight rates well supported, the mood in the dry cargo space is improving. Ordering activity has made a resurgence in 2021, but we still see a number of factors keeping fleet growth limited over the next couple of years. For a detailed outlook of how we see each sector’s fleet developing, please get in touch through your broker.

The current picture

A weak and uncertain freight environment has kept dry bulk ordering low over the last few years, keeping the orderbook at historically low levels. The orderbook currently stands at just over 6% of the trading fleet, amounting to just 57m dwt, the lowest this percentage has been in over 20 years. However we’ve observed a change in sentiment so far this year, as average rates have climbed by as much as 137%, driving an uptick in contracting activity.

The first five months of 2021 saw 189 bulkers added to the orderbook, compared to 111 vessels over the same period last year. Ordering so far this quarter has reached 11.6m dwt, the highest since Q4 2018, with room to grow further as fresh orders emerge this month. This quarter’s ordering marks an increase of 32% QoQ, and is equivalent to 1.3% of the current fleet.

There have been several popular designs within this recent ordering spell. Within our Capesize group category (see p.16 for fleet definitions), contracting so far this quarter is already 27% higher YoY at little under 5m dwt.

Of these newbuildings, 46% (11 vessels) are Newcastlemaxes, and despite this class attracting the most orders over the last few years, this figure represents a fall 35% YoY. Instead, orders of ‘Standard’ Capes have so far lead the growth in Cape ordering increasing five-fold YoY to 12 vessels.

The Panamax sector has however proved the most attractive for investors recently, with April seeing 2.4m dwt in orders. This is the highest monthly figure for this sector since August 2017, largely down to continued popularity of Kamsarmax designs. There has also been a resurgence in Post-Panamax ordering this year, with orders over 2021 so far already totalling 32 ships, 33% higher than 2020’s total and greater than total orders in each year dating back to 2009. Many of these have been contracted as dedicated coal carriers, with a shallow draft and greater intake than the Kamsarmaxes making them optimised for these trades.

Ultramaxes have also proved popular, with this flexible design seeing orders so far this year grow by 33% YoY (though 25% lower relative to 2019) to 15 units. Meanwhile, the Large Handies have seen strong interest in 2021, already topping 2020’s total orders of 800k dwt by 6%. Strength in minor bulk trade in 2021 has made these vessels extremely competitive relative to the larger Supramaxes, with the spread in earnings between these two ship types tightening. This, combined with a relatively low level of Handy deliveries in previous years may be incentivising further orders.

The deceleration in geared ship ordering in recent years may be down to the difficulty of their operation. Some owners entering this sector reportedly find these vessels difficult to manage effectively, and as a result, speculative buyers have focused on the larger vessels.

But despite contracting activity picking up across these markets over the last few months, orders are still well below previous cycle highs. In 2014, for example, a rally in freight rates pushed the orderbook up to 20% of the trading fleet at that time, while in 2008, at the peak of the supercycle, this figure was as high as 80%. Although sentiment is improving, we still see several factors keeping future supply growth limited.

Competition at shipyards

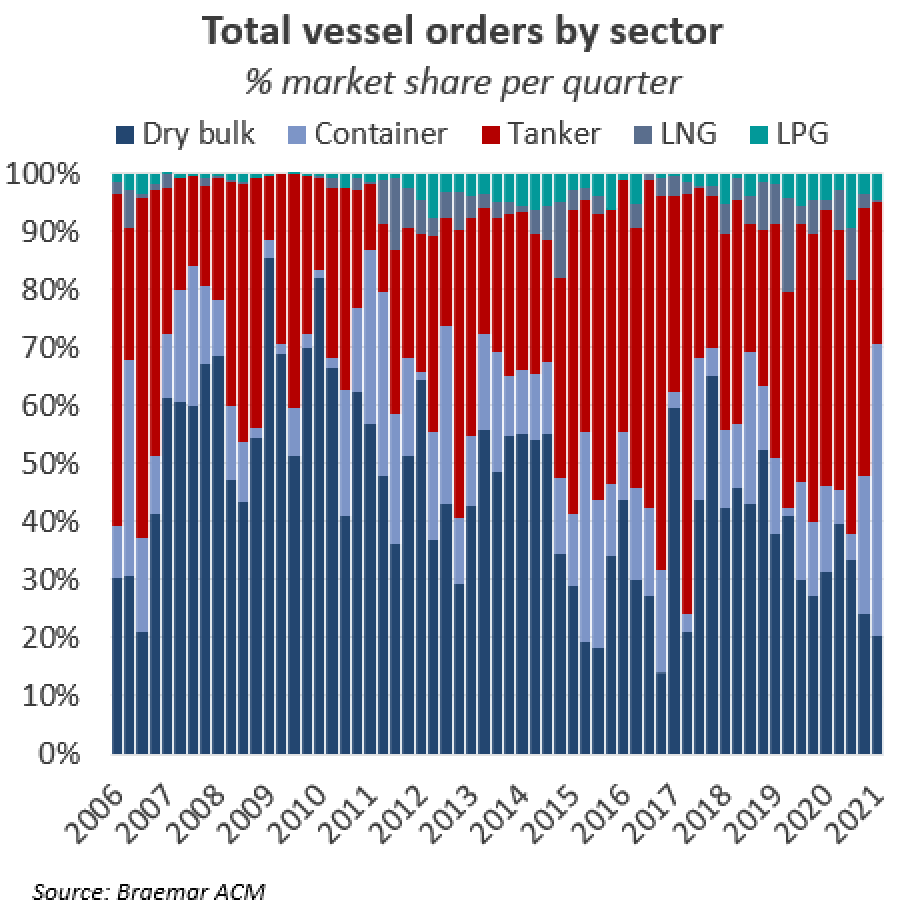

Shipyards have experienced a surge in total demand for newbuildings so far in 2021. Across the different shipping markets, 954 vessels were ordered in the first five months of the year, an increase of 80% YoY and the highest since 2014. But new bulk carriers have taken a backseat, with other types of ships seeing far greater additions to the delivery schedule. Containership newbuildings, especially the bigger classes, have so far dominated the total orderbook this year. As global retail and manufacturing activity recovers from the pandemic, rates for these ships have surged by as much as 360% YoY, pushing owners to expand fleets. Falling to 34% in Q2, over half of total orders placed in Q1 of this year are for these kind of vessels, the highest share of orders for 15 years and the greatest absolute number of orders since Q1 2008. On the tanker side, an already-large orderbook means that new orders for VLCCs and Suezmaxes are reportedly being pushed out to as far as 2024 for delivery. These ships accounted for 21% of orders in Q2.

A scarcity of yard slots due to the boxship ordering surge means that despite an uptick in interest in the dry bulk market, many yards do not have capacity to complete new bulker orders until 2023. Capesize orders are most affected by the spike in Containership interest due to their similar size, with the two ship types often requiring the same yard slots.

Further, many yards in China have been reluctant to agree to orders with extended delivery times due to the current volatility in steel prices. These factors, combined with weak ordering over the last couple of years, means that dry bulk deliveries in 2022 are scheduled to decline by 18% YoY. We expect the total dry bulk fleet to grow by just 2% over this period, the slowest rate since 2012.

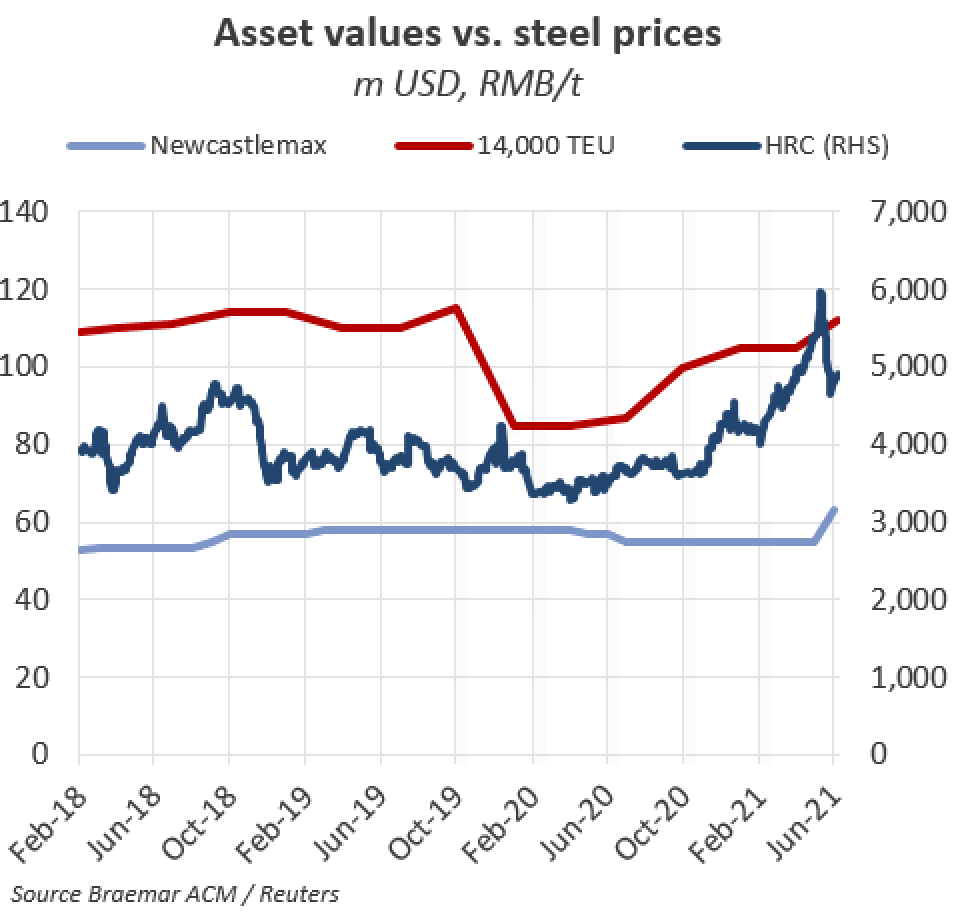

Given the varying newbuilding prices across the shipping markets, it is also unsurprising that yards are prioritising container and tanker orders, which require more steel and are often more profitable to build. Our assessment of the cost of a 14,000 TEU container ship ordered today is around $112m, versus $63m for a Newcastlemax of over 200,00 dwt (the sizes are roughly equivalent in terms of carrying capacity).

The massive rise in steel prices in 2021 has also seen bulker prices sharply increase over just a few months. Many buyers have seen quotes on their ships rise by as much as 21% since February of this year in the case of a Japanese-built Kamsarmax. As a result, some investors have taken a step back from the newbuilding market for the time being. Steel prices on the Shanghai futures exchange for Hot-Rolled Coil (HRC) and Rebar reached all time highs in May to RMB 5,975/t and RMB 4,779/t rising 36% and 75% YoY respectively.

Meanwhile, as orders for new bulk carriers have been supressed by these trends, the second-hand market has been extremely hot, with prices of 5-year old ships up by 33% and 41% in the case of the Kamsarmaxes and Capesizes respectively. We expect activity in this sector to remain heated in the coming months, as owners use this avenue to renew fleets and engage in the strong spot market.

Regulatory uncertainty

As we’ve covered recently, regulations surrounding carbon emissions reductions in shipping pose serious questions for potential investors, and are also driving hesitancy in ordering. With exact rules for the next few years still unclear, would-be owners remain uncertain on whether ship designs ordered today will meet regulatory obligations in the near-future.

The IMO has this week agreed to improve carbon intensity of the overall fleet by 2% annually from 2023 to 2026. The longer-term aim is an overall reduction in the carbon emissions of the fleet by 40% from 2008’s levels by 2030, but it is still unclear how meeting these targets will be facilitated or enforced.

Green financing, outlined by the Green Bond Principles (GBP), has incentivised buyers to consider purchasing new vessels with LNG dual-fuel engines. The reputational gain for companies investing in this technology is attractive, but the hefty price tag and uncertainty over bunkering infrastructure and pricing means that uptake has been limited to the larger ships. In these markets, orders are often backed by long-term charters and trading routes are known in advance.

We currently count three LNG-fuelled bulk carriers in the fleet along with 34 in the orderbook, with the next deliveries slated for 2022. Of these, 32 are Capesizes and LNG-fuelled ships have accounted for almost half of all YTD Cape orders.

Aside from LNG, market participants have researched the use of hydrogen, ammonia and other fuels that offer drastic reductions in emissions. There is however no ready-to-use option in the market currently and for this reason, it is possible that owners are delaying decisions on fleet renewal until more solutions emerge.